Honeycombing in the warehouse is a common phenomenon and is thankfully not caused by an infestation of honey bees! What is honeycombing in the warehousing industry and what does it mean for both the warehouse manager and the customer?

When goods are stored within a warehouse, there is a trade-off between storage efficiency and handling efficiency. To prevent products from being handled multiple times, the warehouse will store only a single item in each lane or pick position. By doing so, the warehouse operator does not have to move items around within the storage area to find the specific item. The fewer times the product is moved, the higher the handling efficiency.

The flip side of this is what happens within the storage area. The lane or pick position only holds one item which may result in an inefficient use of the storage area. Honeycombing is the empty space that results by storing only one item in the storage area. Honeycombing most often occurs as cases or pallets are removed from the storage area. It can also occur upon receipt of the product if there is not enough to completely fill the lane or pick position.

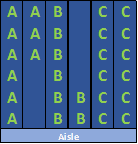

Let's use this illustration as an example. As product A ships out, the space left open in the storage area represents a honeycomb loss of 3 positions. It also appears here that 8 pallets of product B were received, leaving 4 pallet positions open. Product C is fully utilizing all space within the lanes. With room for a total of 36 pallets and 7 open pallet positions, the honeycomb loss is near 20%. Keep in mind, in an actual warehouse each floor spot could have pallets stored 3, 4, 5, or even 6 high depending on the rack height or stackability of the product in a bulk storage position. In this example, if each of the six deep bays stack 4 high, then there are 24 pallets per bay. Therefore total capacity of pallets for this section of warehouse is 144 and the honeycomb loss is 28 pallets.

Vacant pallet positions are very costly to the warehouse. Good inventory control procedures and warehouse management systems help to minimize honeycombing. Storage rates are calculated to include a percentage of honeycombing especially for accounts with heavy case pick and lot picking. Therefore, storage rates will be higher for warehouse customers who require a higher percentage of case picking or lot selection to offset the cost of honeycombing.